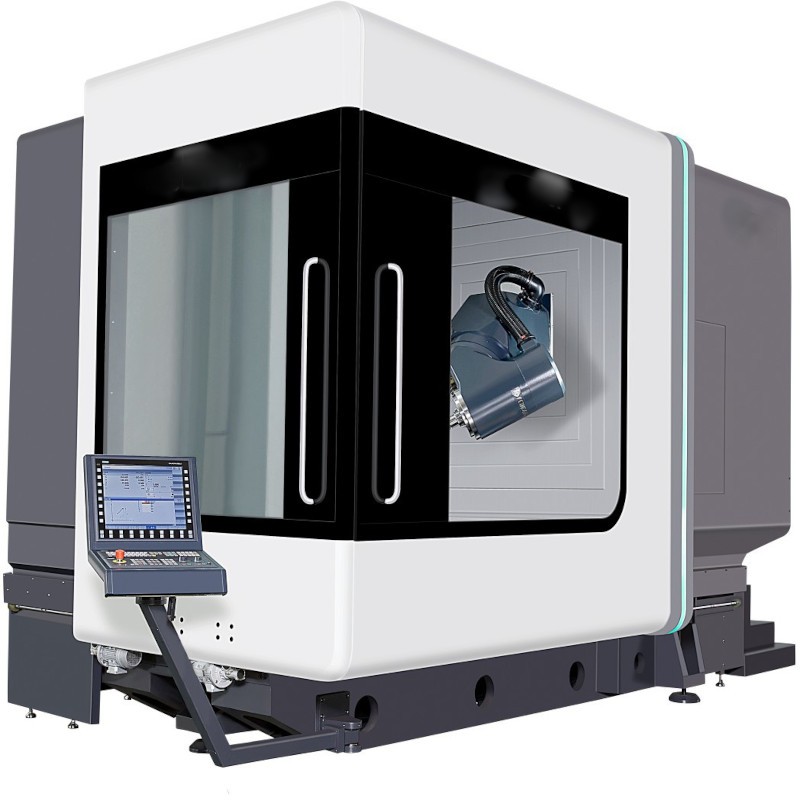

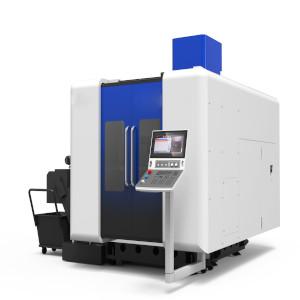

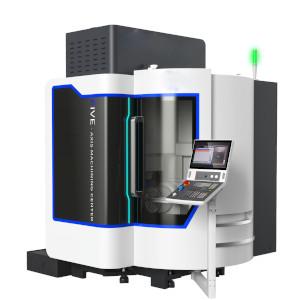

Description

Feature

Highlights

+Fully optimized coolant system

+High rigidity ensures high precision

+Higher efficiency to ensure perfect output

+Convenient and user-friendly operation

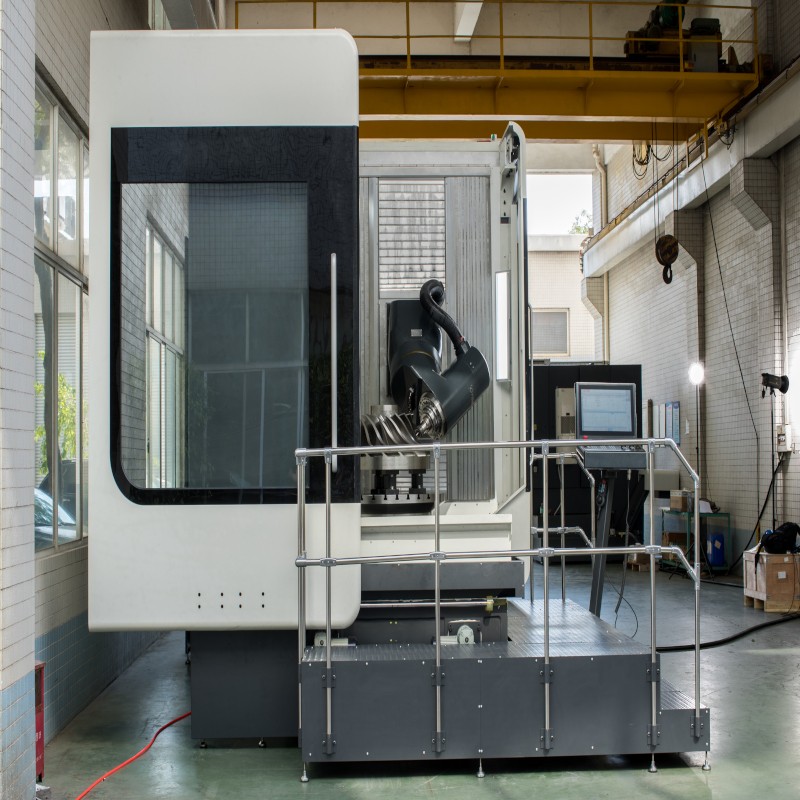

+Panoramic structure easily in maintenance

+Innovative tool management system

+Extremely cost-effective among the same specifications

+B/C axis DD direct drive structure with zero transmission chain for more precise transmission

+X/Y/Z three axis screw hollow cooling system

+B-axis & C-axis high-precision absolute rotary encoder measurement system

+XYZ three linear axes equipped with high-precision linear grating ruler

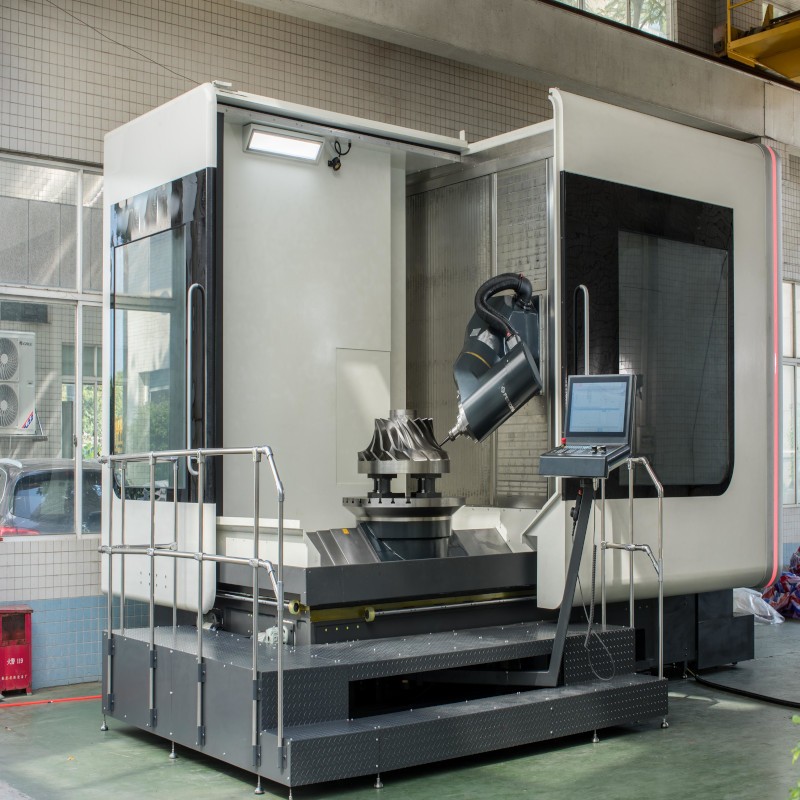

The high stability and high precision structure improved machine overall rigidity. Fundamental structure is further optimized through finite element calculation.

Spindle box

Motor spindle

Spindle box casing

B axis motor

X axis motor

X/Y/Z-axis hollow ball screw

Mill-turn rotary worktable

DD direct drive motor

Basic structure

Direct connected hollow ball screw

Heavy load roller linear guideway for X/Y/Z axis

Technical Parameters

Configuration

Unit

HCNT100P-C

X/Y/Z axis travel

mm

1000*1150*1000

Dist. from horizontal type milling head central to worktable

mm

30-1030

Mill&turn rotary table rated speed

rpm

250

Worktable size

mm

φ1100

MAX. worktable load

kg

Milling: 4000

kg

Turning: 3000

Numerical control swing milling head (B axis)

Standard

Swing range (0=vertical/ 180=level)

degree

-15° to +180°

B axis rated speed

rpm

50

Dist. from vertical type spindle nose to worktable

mm

160 to 1160

Electric spindle MAX. speed

rpm

10000

Power (S1-100%/ S6-40%DC)

kW

42 / 58

Torque (S1-100%/ S6-40%DC)

Nm

215/350

Cutting tool interface

HSK-A100

Tool magazine capacity

position

40

MAX. tool diameter/ length/ weight

mm/ mm/ kg

φ135/ 300/ 12

Cutting tool changing time (tool to tool)

s

4

Drilling (normalizing medium carbon steel)

mm

φ50

Tapping (normalizing medium carbon steel)

M40

Spindle taper

1:10 Taper

Rapid traverse

m/min

40

X/Y/Z positioning accuracy

mm

0.006

X/Y/Z repeat positioning accuracy

mm

0.004

B/C axis positioning accuracy

inch

8"

B/C axis repeat positioning accuracy

inch

4"

Infrared probe

Renishaw OMP60

Tool setting (cutting tool measuring in processing region)

Renishaw NC4F230

Machine height (standard machine)

mm

3650

Main body area (L*W)

mm

5170*3340

Tool magazine area (L*W)

mm

1915*1400

Chip conveyor area (L*W)

mm

3120*1065

Water tank area (L*W)

mm

1785*1355

Complete machine area (excluding water tank) (L*W)

mm

6000*3750

Machine weight

kg

35000

Control system

Siemens ONE