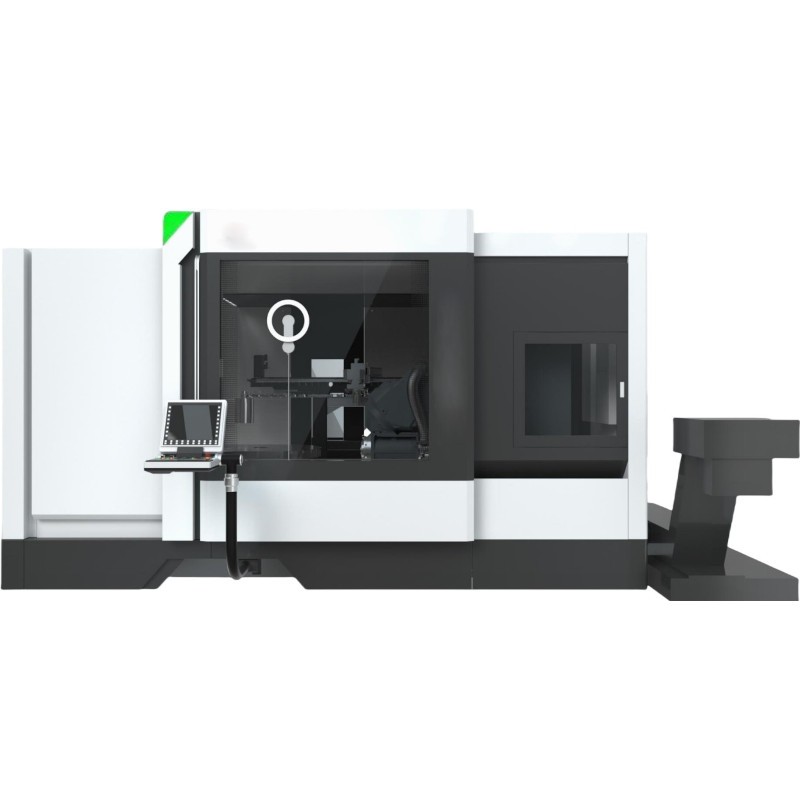

Description

Feature

Bed structure

• The machine tool adopts a wall-type longitudinal bed layout and a vertical and horizontal milling head structure. The solid cast iron bed and wall-type columns ensure the high rigidity, high dynamic performance and high stability of the machine tool, and the best vibration absorption during operation and processing.

• The large column and X-axis three-guide design reduce the weight of moving parts, achieve high dynamic performance and stability, and lower energy consumption.

• The CNC rotary table is located on the linear axis and has a strong load-bearing capacity.

Drive structure and spindle

• High-precision ball screw, built-in constant temperature cooling of the screw center, equipped with precision grating scale to ensure processing accuracy.

• XYZ axis is driven by Siemens 1FT7 series water-cooled servo motor, with high dynamic accuracy and stability.

• The work surface and base of the CNC rotary table are made of high-strength ductile iron, which has extremely high rigidity. The center support bearing uses high-precision turntable special bearings, which are directly driven by the torque motor, and the transmission is stable without reverse clearance.

• The rotary table core shaft part has reserved air and oil circuit interfaces to facilitate the realization of automatic clamping and function expansion.

MC Series Spindle

• All use precision roller guide rails, which have higher load capacity.

Equipped with German KESSLER high-precision electric spindle, adopts circulating constant temperature cooling method, bearing oil and gas lubrication, and achieves high torque and high speed operation. The spindle can be equipped with tool center flushing function. The spindle is standard 12000rpm and optional 10000rpm.

• Power (S1/S6-40%): 48/71KW

• Torque (S1/S6-40%): 300/452Nm

• Speed: 12000rpm

• Tool taper: HSK-A100

Technical Parameters

|

Configuration |

Unit |

HCNT-MC125 |

HCNT-MC125T |

|

|

Basic information |

X/Y/Z axis travel |

mm |

1250/1250/1000 |

|

|

B axis swing range (0=vertical/180=horizontal) |

degree |

-30/+180 |

||

|

Rotary table rotation range |

degree |

360 |

||

|

Spindle central to pallet dist. (horizontal milling head) |

mm |

50~1050 |

||

|

Spindle central to pallet dist. (vertical milling head) |

mm |

-300~950 |

||

|

Spindle nose to palletcentral dist. (horizontal milling head) |

mm |

-200~1050 |

||

|

Spindle nose to pallet central dist. (vertical milling head) |

mm |

150~1150 |

||

|

Worktable size |

mm |

Φ1250 |

||

|

MAX. load of worktable |

kg |

2500 |

2000 |

|

|

Spindle |

MAX. spindle speed/ taper |

rpm |

12000/HSK-A100 |

12000/HSK-T100 |

|

Power (S1/S6-40%) |

kW |

48/71 |

||

|

Output torque (S1/S6-40%) |

Nm |

300/452 |

||

|

Feed system |

X/Y/Z axis fast moving speed |

m/min |

60 |

|

|

MAX. cutting feed rate |

m/min |

20 |

||

|

B axis speed |

rpm |

30 |

||

|

Rotary table speed (milling/ turning) |

rpm |

35 |

500 |

|

|

Positioning accuracy |

X/Y/Z axis (Germany VDI3441 standard) |

mm |

0.008 |

|

|

B/C axis (Germany VDI3441 standard) |

arcsec |

8 |

||

|

Repeat positioning accuracy |

X/Y/Z axis (Germany VDI3441 standard) |

mm |

0.005 |

|

|

B/C axis (Germany VDI3441 standard) |

arcsec |

5 |

||

|

Automatic tool changing system |

Number of cutting tools |

pcs |

40/60 |

|

|

MAX. cutting tool length |

mm |

400 |

||

|

MAX. tool diameter/ no tool adjacent |

mm |

Φ125/Φ250 |

||

|

MAX. tool weight |

Kg |

25 |

||

|

CNC system |

Siemens/ Heidenhain |

—— |

Sinumerik one/ Heidenhain TNC 640 |

|

|

Machine parameters |

Total height |

mm |

3800 |

|

|

Length*width (including maintenance and operation space) |

mm |

5800*5700 |

||

|

Weight |

Kg |

23000 |

||

|

Power requirements |

KW |

95 |

120 |

|

|

Optional configurations |

Tool measurement, workpiece measurement, five-axis coordinate conversion vector measurement and correction function, tool internal cooling system,rotating window, oil mist collector, optimal surface function, OPC UA data acquisition function, water gun, tool identification system, machine tool post-processing, spindle thermal compensation function, automatic door, machine tool anti-collision system. |

|||