Description

Feature

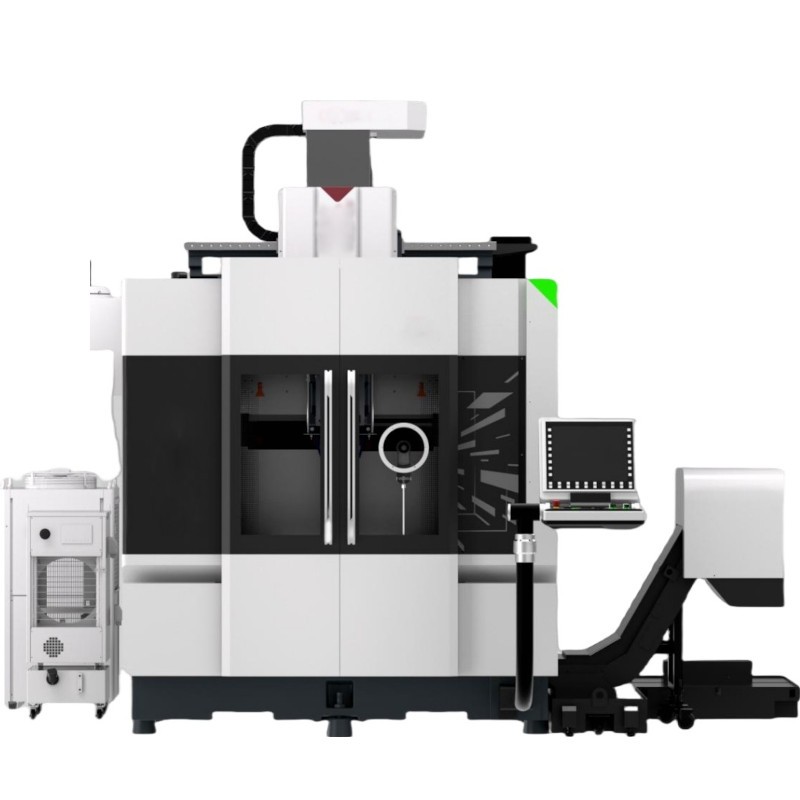

Overall structure

• The gantry crane structure is adopted, and the dynamic rigidity of the whole machine is good, which can efficiently meet the requirements of high-strength five-axis linkage interpolation processing.

• The fully enclosed armor internal protection prevents chips and coolant from entering the machine tool, so as to avoid wear and corrosion of the guide rails and ball screws.

• The top is equipped with a retractable protective cover to facilitate the disassembly and assembly of the workpiece, and the front door can be equipped with automatic opening and closing mode to meet the needs of automated production lines.

Drive structure

• All adopt precision heavy-duty roller guide rails with higher load capacity.

• Y-axis dual-drive structure, stable transmission, high dynamic accuracy.

• High-precision ball screw, built-in screw center constant temperature cooling, equipped with precision grating ruler, full closed-loop control to ensure processing accuracy.

Control system

• Siemens high-end five-axis linkage CNC system Sinumerik one.

• Simple interactive programming method; PreProcessing simulation to ensure high reliability.

• Efficient tool management.

Technical Parameters

|

Configuration |

Unit |

HCNT-MG80 |

HCNT-MG80T |

|

|

Basic information |

X/Y/Z axis travel |

mm |

800/900/620 |

|

|

A axis swing range |

degree |

±120 |

||

|

C axis rotation range |

degree |

360 |

||

|

Dist. from spindle nose to worktable |

mm |

120-740 |

||

|

Worktable size |

mm |

Φ800 |

||

|

MAX. worktable load |

kg |

1200 |

1000 |

|

|

MAX. rotation diameter of worktable |

mm |

Φ1000 |

||

|

Spindle |

MAX. spindle speed/ taper |

rpm |

20000/HSK-A63 |

20000/HSK-T63 |

|

Power (S1/S6-40%) |

kW |

25/40 |

||

|

Output torque (S1/S6-40%) |

Nm |

87/135 |

||

|

Feed system |

X/Y/Z axis fast moving speed |

m/min |

50 |

|

|

MAX. cutting feed rate |

m/min |

0.001~20 |

||

|

A axis speed |

rpm |

30 |

||

|

C axis speed |

rpm |

80 |

800 |

|

|

Positioning accuracy |

X/Y/Z axis (Germany VDI3441 standard) |

mm |

0.005 |

|

|

A/C axis (Germany VDI3441 standard) |

arcsec |

8 |

||

|

Repeat positioning accuracy |

X/Y/Z axis (GermanyVDI3441 standard) |

mm |

0.003 |

|

|

A/C axis (Germany VDI3441 standard) |

arcsec |

5 |

||

|

Automatic tool changing system |

Tool magazine quantity |

pcs |

40 (optional 40*2) |

|

|

MAX. cutting tool length |

mm |

300 |

||

|

MAX. cutting tool diameter/ no tool adjacent |

mm |

Φ75/Φ125 |

||

|

MAX. cutting tool weight |

Kg |

8 |

||

|

CNC system |

Siemens / Heidenhain |

—— |

Sinumerik one/ Heidenhain TNC 640 |

|

|

Machine parameters |

Total height |

mm |

3730 |

|

|

Length*width |

mm |

5460*4650 |

||

|

Weight (excluding accessories) |

Kg |

21000 |

22000 |

|

|

Power requirements |

KVA |

90 |

120 |

|

|

Optional configurations |

Tool measurement, workpiece measurement, five-axis coordinate conversion vector measurement and correction function, tool inner coolant system,rotating window, oil mist collector, optimal surface function, OPC UA data acquisition function, water gun, tool identification system, machine tool post-processing, spindle thermal compensation function, automatic door, machine tool anti-collision system. |

|||